With the continuous advancement of semiconductor manufacturing technology, chip size continues to shrink, and the sensitivity to impurities has significantly increased. The importance of G5-level wet electronic chemicals in advanced processes has become increasingly prominent, and its quality is directly related to the electrical performance and final yield of the chip. However, due to the limitations of technology and raw materials, domestic G5-level "ultra-pure chemical packaging materials" products are scarce.

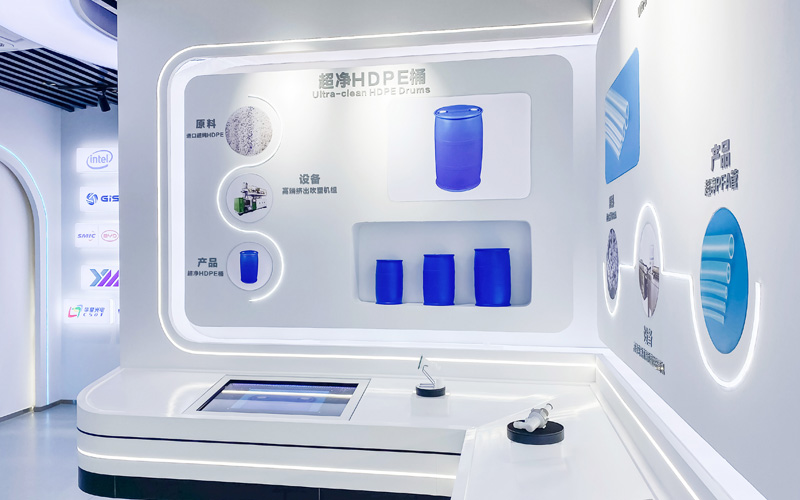

Through long-term R&D investment and technical research, Baoshili has made major breakthroughs in the field of G5-level chemical packaging materials, and successfully developed ultra-pure chemical packaging materials that meet G5-level standards-200L ultra-clean plastic packaging containers, and entered the product verification stage.

With the continuous increase in the production capacity of 8-inch and 12-inch wafers in mainland China, the demand for mid-to-high-end wet electronic chemicals has also increased significantly. In particular, the unit production capacity of 12-inch wafer manufacturing is much higher than that of 8-inch wafers (about 4.6 times that of 8 inches), which further promotes the demand for G5-level wet electronic chemicals.

The industry's leading wafer foundries have large-scale 12-inch wafer fab expansion projects in many locations in China, covering from mature processes to advanced FinFET processes. The advancement of these projects has created a huge demand for ultra-high-purity general chemicals. For example, in the many cleaning and etching steps of logic chip manufacturing, a large amount of G4, G5 or even higher purity levels of general wet electronic chemicals are required, including high-purity sulfuric acid (H₂SO₄), high-purity hydrofluoric acid (HF), high-purity hydrogen peroxide (H₂O₂), high-purity isopropyl alcohol (IPA), high-purity ammonia (NH₄OH), high-purity hydrochloric acid (HCl), etc. As logic chip process nodes move toward 14 nanometers and smaller, the number of cleaning and etching steps increases significantly, and the consumption of these ultra-high-purity chemicals also increases exponentially.

The core of competition in the field of wet electronic chemicals lies in the "purity competition", especially in the high-end product lines of G4 and G5 grades, where the control requirements for pollutants such as metal impurities and particulate matter have reached the extreme.

The G5 standard mainly reflects:

Metal impurity control: By using high-purity raw materials and advanced production processes, we strictly control pollution during the production process to ensure that the metal impurity content in the materials is lower than the ppb (parts per billion) or even ppt (parts per trillion) level. For example, for common metal impurities such as iron, copper, and aluminum, their content must be controlled at an extremely low ppt level to avoid adverse effects on the chip manufacturing process.

Particle control: High-precision filtration and purification technology is required to remove tiny particles from the material. Under the G5 standard, the number of particles larger than a certain size per unit volume must be below the specified limit.

Organic impurity control: The removal of organic impurities is also crucial. By optimizing the production process and using efficient purification equipment, the content of organic impurities in the material can be reduced to a level that meets the requirements. In addition, it is also necessary to strictly control organic pollution in the production environment to ensure product quality.

Baoshili G5-grade chemical packaging materials-200L ultra-clean plastic packaging containers have excellent chemical resistance, low ion precipitation characteristics and ultra-high cleanliness, and are suitable for the storage and transportation of electronic-grade chemicals.

The products are independently developed by Baoshili and produced in clean workshops. They use imported high-purity high-density polyethylene (HDPE) raw materials. Through hollow blow molding technology, based on the good chemical stability and wide compatibility of HDPE, they can be applied to a variety of high-purity wet chemicals such as acids, alkalis and organic chemicals; the products have 14 independent intellectual property rights, covering the independent research and development and production of supporting components such as standard covers, gas phase covers, liquid phase covers, suction tubes, and barrel openers.

At present, Baoshili G5-grade chemical packaging materials have entered the product verification stage and have performed well in many performance tests.

According to the forecast of the China Electronic Materials Industry Association, the global wet electronic chemical market size will reach 82.52 billion yuan in 2025, with a compound growth rate (CAGR) of 8.9% from 2022 to 2025. Among them, the performance of the Chinese market is particularly outstanding, and it is expected that the domestic market size will increase to 29.275 billion yuan in 2025.

In such a market context, Baoshili G5-grade chemical packaging material-200L ultra-clean plastic packaging container is expected to fully benefit from the rapid growth of the market with its technological leadership and product advantages.

online service

online service +86 592 625 8655-ext-622

+86 592 625 8655-ext-622 carrie@xmbsl.com

carrie@xmbsl.com carrielin36

carrielin36 +8613850062482

+8613850062482