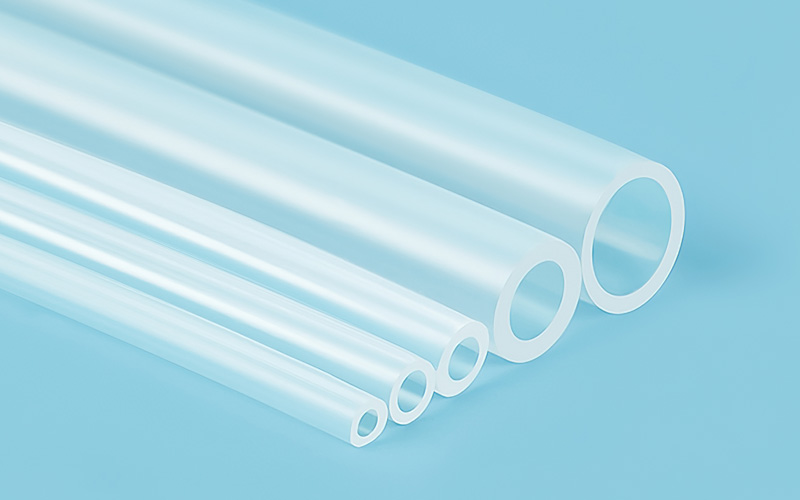

In the front-end manufacturing process of semiconductors, the purity of chemical materials is directly related to product quality and production efficiency. As a professional manufacturer focusing on ultra-clean PFA pipe fittings for semiconductor-grade chemical transportation materials, Baoshili will show you the 5 key differences between Ultra-Clean PFA Tube VS ordinary PFA Tube today.

The purity of Ultra-Clean PFA Tube is its core advantage. It contains almost no impurities, thanks to the use of industry-recognized high-purity raw materials, such as Daikin SH grade and DuPont HP series. These top-grade raw materials ensure the purity of pipe products and avoid affecting the high-precision production process.

Ordinary PFA Tube may contain more impurities due to the low purity of raw materials, which can easily cause product defects in the rigorous semiconductor manufacturing process.

In terms of mechanical properties, Ultra-Clean PFA Tube also perform well. Through precise production processes, the molecular chains are arranged more regularly, giving the pipes higher strength and toughness. Whether facing continuous high-pressure transmission or frequent mechanical vibrations, ultra-clean PFA pipe fittings can maintain a good shape.

However, due to the limitations of the production process, ordinary PFA Tube can only meet basic usage requirements and are prone to wear and deformation in high-intensity, long-cycle application scenarios.

Super strong chemical corrosion resistance is another highlight of Ultra-Clean PFA Tube. In the semiconductor manufacturing process, pipes need to be exposed to various strong acids, strong alkalis and organic solvents. Ultra-Clean PFA Tube can resist the erosion of almost all chemical reagents with their unique molecular structure, ensuring that they are not contaminated or degraded in chemical cleaning, etching and other links.

Although ordinary PFA Tube also have a certain degree of corrosion resistance, their insufficient purity leads to the precipitation of impurity ions when in contact with high-purity chemical reagents for a long time, which is easy to contaminate chemical reagents and thus affect product quality.

With the above-mentioned excellent performance, Ultra-Clean PFA Tube have become the preferred material for high-end manufacturing industries such as semiconductors. In the semiconductor industry, it is widely used in chemical infusion pipelines and gas delivery pipelines in the chip manufacturing process, safeguarding the high-precision and high-purity environment of chip production.

Ordinary PFA Tube are more used in scenarios with relatively low performance requirements, such as wire casings, general industrial pipelines, etc.

Baoshili focuses on the research and development and production of semiconductor-grade Ultra-Clean PFA Tube, and has advanced production equipment and a strict quality control system. From the careful selection of raw materials, to the fine control of production processes, to the strict testing of finished products, every link ensures the excellent quality of the products. Choosing Baoshili Ultra-Clean PFA Tube is to choose a reliable guarantee for your production process.

online service

online service +86 592 625 8655-ext-622

+86 592 625 8655-ext-622 carrie@xmbsl.com

carrie@xmbsl.com carrielin36

carrielin36 +8613850062482

+8613850062482