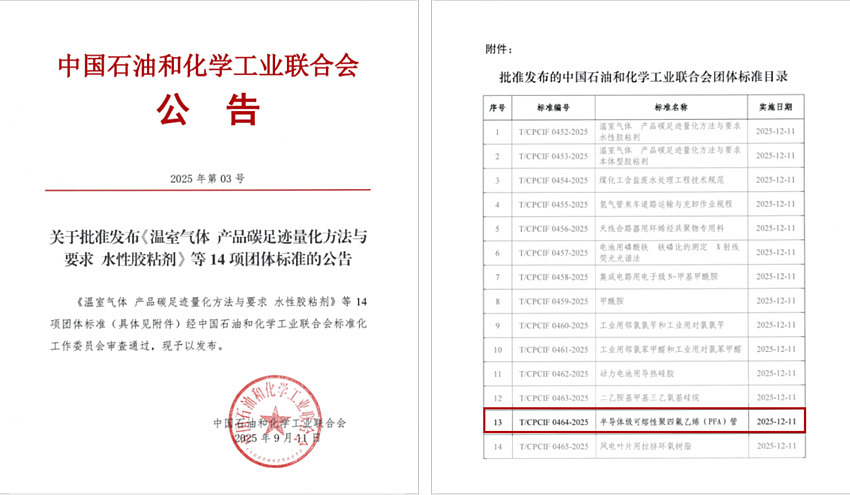

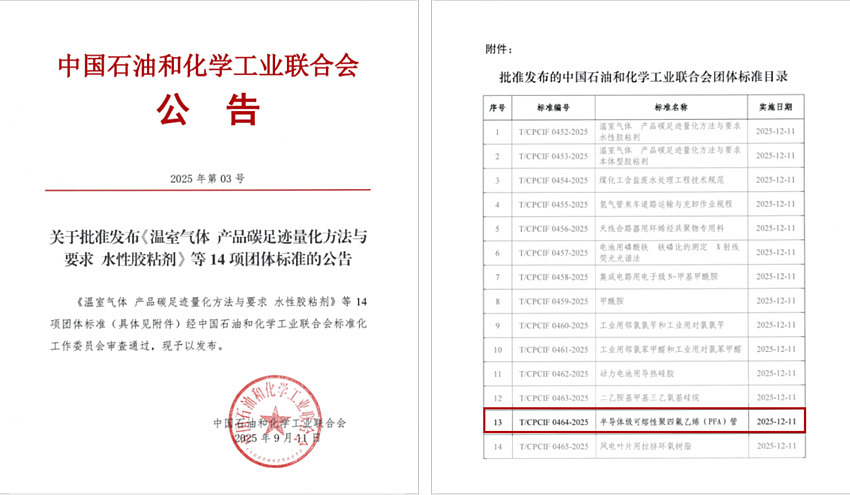

Recently, the China Petroleum and Chemical Industry Federation officially issued an announcement on 14 group standards. Among them, the Group Standard for "Semiconductor Grade Ultra-Pure Fusible Polytetrafluoroethylene (PFA) Tube" (T/CPCIF 0464-2025), led by Baoshili and co-participated by more than 20 high-tech enterprises specializing in ultra-pure fluoropolymers, has been reviewed and approved by the Standardization Working Committee of the China Petroleum and Chemical Industry Federation, and will be formally implemented on December 11, 2025.

The formulation and implementation of this standard will effectively fill the gap in domestic standards for ultra-high purity materials used in the semiconductor industry. It is of great significance for standardizing product quality, improving device yield, and supporting the safety and high-quality development of the semiconductor industry chain.

The semiconductor industry is developing rapidly towards higher integration and precision, putting extremely high demands on the purity, stability, and reliability of key components for the delivery of wet electronic chemicals. As a critical component for transporting ultrapure water and chemicals in semiconductor manufacturing, the quality of PFA tubes directly affects the yield and performance of chip production.

Based on the international SEMI F57 specification and combined with the actual development of China’s semiconductor industry, the Group Standard for "Semiconductor Grade Ultra-Pure Fusible Polytetrafluoroethylene (PFA) Tube" has for the first time systematically specified key technical indicators for semiconductor-grade PFA tubes, including dimensional specifications, appearance, Total Organic Carbon (TOC) content, surface roughness, and leaching amounts of metal and non-metal ions.

Notably, multiple technical indicators of this standard are stricter than international standards. For example, the TOC content requirement is ≤ 2000 μg/m² (compared to ≤ 40000 μg/m² in SEMI F57), and the limits for leaching amounts of multiple metal ions have also been significantly raised. These stricter provisions reflect China’s high-standard requirements in the field of high-end semiconductor materials and will effectively improve the reliability of domestic semiconductor components.

As the leading drafting unit of this standard, Baoshili has provided key support such as critical experimental verification data for the standard’s formulation, leveraging its technological accumulation and industrialization experience in the fluoropolymer field.

For a long time, Baoshili has successfully developed semiconductor-grade Ultra-Clean PFA Tubes by making breakthroughs in key process technologies such as ultra-clean PFA plasticization, extrusion, vacuum sizing, traction and winding, and dimensional control. It has also integrated ultra-pure material formulations and advanced high-temperature and corrosion-resistant precision equipment, while conducting professional technical research on the relationships between key performance indicators of tubes in the system—including rheological properties, decomposition characteristics of unstable end groups, dimensional tolerance, surface smoothness, corrosion resistance, and metal ion leaching amount.

Baoshili is not only the leading drafter of this standard but also an active promoter. From the demonstration of the standard’s project initiation to the compilation of technical content, Baoshili has actively contributed resources, and conducted joint discussions, verification, and improvement with participating units, fully demonstrating its sense of responsibility and commitment as an innovative enterprise in the ultra-pure fluoropolymer field.

The China Petroleum and Chemical Industry Federation (hereinafter referred to as "CPCIF") is a national, comprehensive social industry organization with service and certain management functions in the petroleum and chemical industry. Its key functions include "participating in the formulation of industry plans and conducting preliminary demonstration for major investment, development, technological transformation, and technology introduction projects in the industry".

The implementation of this standard will effectively standardize the production and inspection processes of semiconductor-grade ultra-pure PFA tubes, improve the consistency of product quality, reduce the chip defect rate caused by pipeline contamination, and contribute to the independent and controllable high-quality development of China’s semiconductor industry chain.

online service

online service +86 592 625 8655-ext-622

+86 592 625 8655-ext-622 carrie@xmbsl.com

carrie@xmbsl.com carrielin36

carrielin36 +8613850062482

+8613850062482