With the continuous advancement of chip manufacturing technology, wafers are becoming increasingly sensitive to impurity content. During the wafer manufacturing process, the impurities introduced have a crucial impact on chip yield and production efficiency. Therefore, advanced cleaning equipment plays a key role in semiconductor production.

Founded in 2005, ACM (Shanghai) has always been a leading company in the integrated circuit equipment industry and was rated as one of the "Top Five Semiconductor Equipment Companies in China". Its product line is extensive, including single wafer and tank wet cleaning equipment, electroplating equipment, etc. It integrates R&D, design, manufacturing and sales, focusing on providing high-performance, low-energy consumption process solutions to semiconductor chip manufacturers.

With the world's first SAPS/TEBO megasonic cleaning technology and Tahoe single-wafer tank combined cleaning technology, Shengmei has solved the problem of cleaning organic contamination and particles after wafer etching, and improved the production efficiency and product yield of semiconductors. , one of the few internationally competitive semiconductor-specific equipment providers in mainland China.

Semiconductor cleaning process

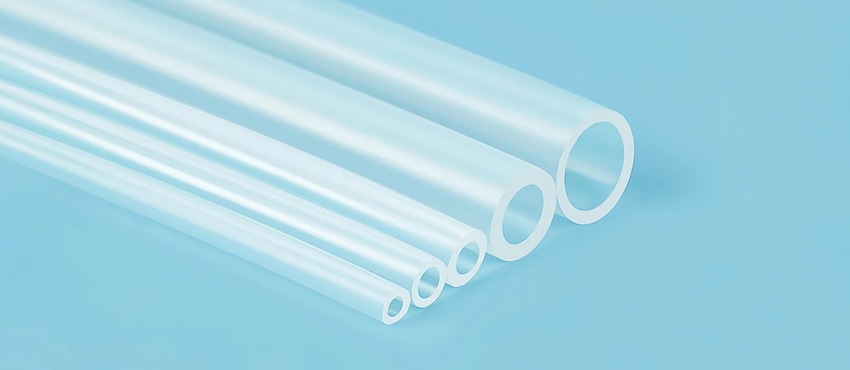

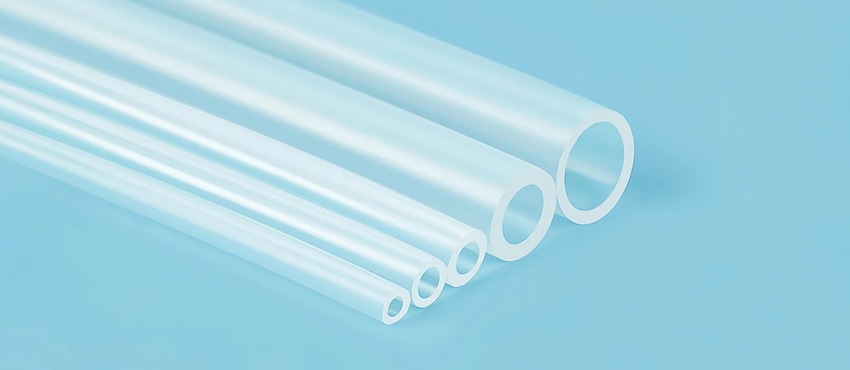

The key role of Ultra-Clean PFA Tube

In the semiconductor manufacturing process, wet cleaning is a crucial link. High-tech technologies such as the Space Alternating Phase Shift (SAPS) megasonic wave independently developed by ACM, combined with functional water, can more efficiently remove impurities such as fine particles and photoresist on the wafer.

Functional water is an aqueous solution containing specific dissolved gases, combined with a small amount of chemicals, and uses high-frequency vibrations generated by SAPS megasonic technology to greatly improve cleaning efficiency.

The important role of Baoshili Ultra-Clean PFA Tube is to transport functional water, ensure the high purity and impurity-free transmission of functional water, and protect the production process of ACM (Shanghai).

The only domestic supplier of PFA Tube

Three major advantages of Baoshili

It is worth noting that Baoshili is the only domestic PFA Tube supplier of ACM (Shanghai). Through continuous independent technology research and development and excellent product performance, it has broken the status quo of top semiconductor companies only purchasing imported PFA Tube, and has taken the lead in realizing Domestic replacement of semiconductor grade PFA Tube.

At present, Baoshili Ultra-Clean PFA Tube has three leading advantages:

1. Performance advantages: It uses imported Daikin AP 231SH high-purity raw materials and is produced through a high-precision corrosion-resistant PFA pipe extruder to ensure the high purity and excellent performance of the product.

2. Quality testing: In the 100-level laboratory, cutting-edge equipment such as Agilent ICP-MS/MS 8900 is used to conduct product quality testing to ensure the standardized production of each batch of finished products.

3. Independent research and development of production technology: Having a complete production process to ensure the stability and reliability of products.

With the rapid development of the domestic semiconductor industry, as the leading domestic PFA manufacturer, Baoshili Ultra-Clean PFA Tube are being widely used in various semiconductor production links, providing specialized parts and components for top domestic semiconductor companies, and jointly promoting industrial upgrading.

online service

online service +86 592 625 8655-ext-622

+86 592 625 8655-ext-622 carrie@xmbsl.com

carrie@xmbsl.com carrielin36

carrielin36 +8613850062482

+8613850062482